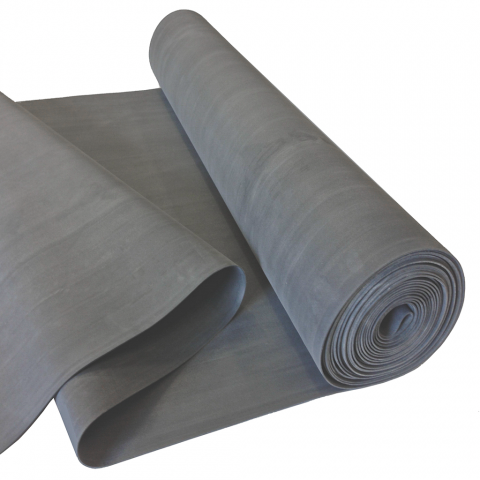

ClassicBond® 1.5mm EPDM Rubber Roof Membrane

Premium 1.5mm ClassicBond® One Piece EPDM Rubber Membrane

Our Premium ClassicBond® One Piece EPDM Rubber Membrane Is 30% thicker than standard EPDM which makes it the ideal choice for almost all roofing projects, Especially commercial roofs. The added thickness helps provide better tear resistance and extra durability. It is also more forgiving on uneven surfaces.

ClassicBond is the original EPDM roofing system with a proven track record of over 50 years service life. Recognised as one of the most reliable, durable and sustainable materials for your flat roof. ClassicBond is manufactured by Carlisle-Syntec who Pioneered EPDM Roofing systems in the 1960’s

BBA Certified & preferred by roofing professionals, ClassicBond is tangibly more pliable, slate grey in colour and is the ideal EPDM rubber membrane for both large and small flat roofs. Click For BBA Certificate

Specification

The rubber roof EPDM membrane is sold by the running metre from large pre-joined sheets starting at 0.5m in width and increasing in 0.5m increments up to 30.5 metres in length, by 15.25 metres in width. This means no on-site joining is required as long as the roof does not exceed these measurements and makes the ClassicBond EPDM the best for quick and easy installation.

ClassicBond EPDM is available in two thicknesses:

-

1.2mm (standard)

-

1.52mm (commercial)

Why Choose ClassicBond®?

The ClassicBond roof system is designed to be cost effective and much faster than traditional roofing systems. For most applications the membrane is cut to the size of your roof and supplied as one single piece, trimmed to size and finished off with the correct drip, kerb edge and wall up-stand trims.

Due to the nature of the material it will easily bend and conform to the contours of your roof and is applied using adhesives which means no flames or hot liquids making it a safer option for installers and home-owners.

As EPDM is not affected by extremes of temperature the membrane will not crack, peel or split and is covered by our 20 Year Manufacturers membrane guarantee.

You might also need

If you’re buying for a new roof or replacing an old one, you will need to consider the following components in your roof kit...

- Adhesives

- Tapes

- Drains

- Edge Trims

- Tools

SKU |

CB-15 |

|---|---|

Stock Type |

Warehouse Fulfilled |

Thickness |

1.50 mm |

Max Length |

30.5 m |

Brand Name |

ClassicBond |

-

ClassicBond® 1.2mm EPDM Rubber Roof Membrane£12.24 £10.20

ClassicBond® 1.2mm EPDM Rubber Roof Membrane£12.24 £10.20 -

ClassicBond Pro Fleece Reinforced EPDM - 18.58m2£570.00 £475.00

ClassicBond Pro Fleece Reinforced EPDM - 18.58m2£570.00 £475.00 -

Flat Rubber Roof Kits£359.77 £299.81

Flat Rubber Roof Kits£359.77 £299.81 -

EPDM Porch Roof Kits£186.02 £155.02

EPDM Porch Roof Kits£186.02 £155.02 -

Dormer Rubber Roof Kits£168.92 £140.77

Dormer Rubber Roof Kits£168.92 £140.77 -

Garage Rubber Roof Kits£436.44 £363.70

Garage Rubber Roof Kits£436.44 £363.70 -

Shed Rubber Roof Kit - SkyGuard®£46.20 £38.50

Shed Rubber Roof Kit - SkyGuard®£46.20 £38.50